3D Printing is a new technology that enables printing three dimensional objects. 3D printing has many similarity to a conventional printing but here successive layers are printed by additive processes. In fact 3D printing is just like normal printing that has extended to its third dimension. This technology is around us from mid eighties, evolved since then and now it has many medical and technological advantages with uses from treating and replacing scar tissues, total organ implant to even building a part of the house.

Bioprinting a 3d printing process used in health and medical sector, that holds the potential of printing body parts of living objects like human body parts with help of a liquid mixture called bio ink made of biodegradable gel and actual living cells of organism like humans and animal cells. Some of the doctors in north carolina of US have started implanting these printed body part in actual humans. The implantation involves the placement of any 3D printed parts directly into the patients and recovery involves the adhering of the human cells in the printed part that is extracted from the same patient leaving the biodegradable gel to wear off in the process. Skin printing projects are also useful for printing body cells for healing wounded areas of human and similar such projects are currently funded by us military to treat injured soldiers. Bioprinting is not yet reached its functional stage and still take years to implement to be utilized on conventional or domestic scale.

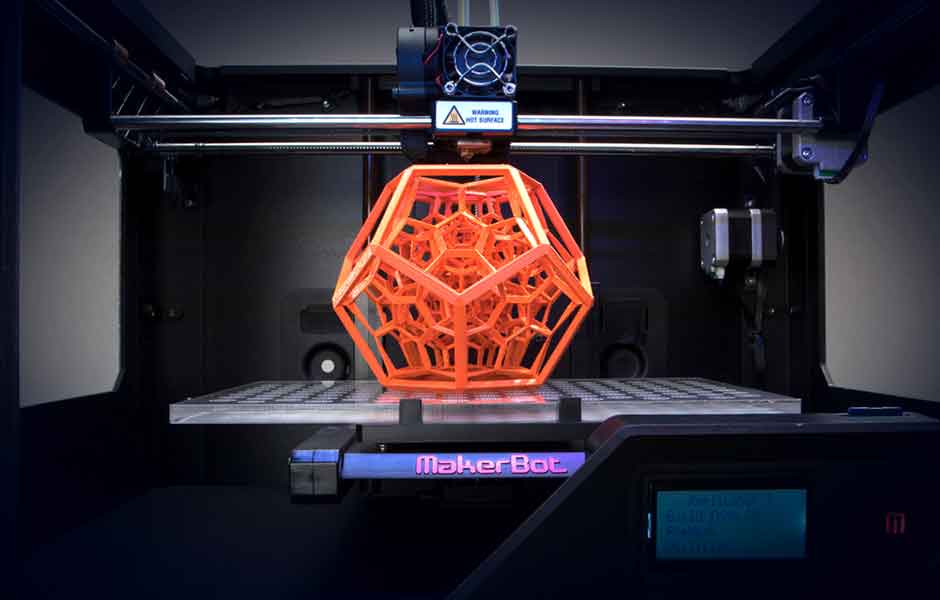

As stated earlier 3D printing isn’t new technology it was used earlier in many industries for prototyping. But this technology which emerged in industries has grown faster and now it’s in a stage, ready of commercial use. 3D printing technology can print scanned, sketched images or digital blue print of literally any object into real three dimensional object. Thus 3D printing makes duplication of real objects from digital copies. Real world examples can be seen in case of certain airplanes where part like air ducts are 3D printed, movies like iron man also has its costumes printed by 3D printing and few peoples in US also have their houses built by 3D printing. 3D printing involves printing scanned or sketch copies of object layer by layer by extruding a liquid usually plastic or any other substrate material for the object which is in a semifluid form and hardens with time to form the real object. 3D printing can also use lasers to resins and metals to form hard material objects.

Companies like GE, Boeing, Siemens, Nike and Rolls-Royce are some of the early adopters of 3D printing making it over $6 billion industry in short span of three years according to a report by Wohlers Associates, a consulting company in Colorado US. Estimation by a research firm called Gartner states that around 14,000 units of 3D printer will be shipped across markets of Asia Pacific alone by 2017. Wipro, the popular IT giant in India has invested around $ 2 million (12 crores rupees) in 3D printing plant with lone printers and has took several projects of 3D printing and additive manufacturing from customers like Hindustan Aeronautics Limited to build Vane guides. Recently a large chain of hospitals in Mumbai called upon Mr. Maltesh Somasekarappa head of 3D printing in Wipro to print a 3D titanium skull piece for a patient who had meet with an accident and later the printed skull was successfully shipped and implanted to the patient. Wipro’s partner Singapore based EOS specialized in additive manufacturing has sold its 3D printer to Wipro which has encouraged its 3D printing projects further. Apart from this global player GE also has plans to make fuel nozzles for its new leap jet engines. Though Additive Manufacturing or 3D printing is not as qualifying compare to conventional manufacturing scale but 3D printing holds its potential of manufacturing on smaller scale and who knows may be in future it will scale up but that too on the other side has to be a billion dollar unit also. And so do the IT companies like Wipro still holds the hopes to make high quality of 3D printed goods for health, aerospace and defense sectors.

In daily life also there is a much need of 3D printing as well, like if you want to make a broken air container hose, or make a cover case for your laptop or mobile phone you can simply built it with a 3D printer using the scanned copies of that objects. Also 3D printer can be a means of business as well where scaled production of indemand tools or objects could meet the local needs and generate revenue. In many countries, soon 3D printing will reach retail sector for use at home and factories, the estimated price of reliable 3D printers comes around $2200 or more. One of the popular 3D printer manufacturers are Maker Bot, they have there own website called thingiverse for downloading free digital images that can be used in 3D printer and turn into real dimensional objects.

If you are a retailer selling this product join as seller on Finysel online shop and start selling on our store.

- 10 Best Water Purifiers: Health & Safety Benefits - February 18, 2024

- How to Avoid Sexual Health Problems - January 24, 2024

- Top 10 Dishwashers: The Ultimate Guide - October 20, 2023

I like 3D printers

Very amazing blog certainly the 3D printers have changed and become more interesting and easy to use.